- June 12, 2025

- Posted by: wellcoindustries

- Categories: Erosion Control, Jute Mesh

Introduction

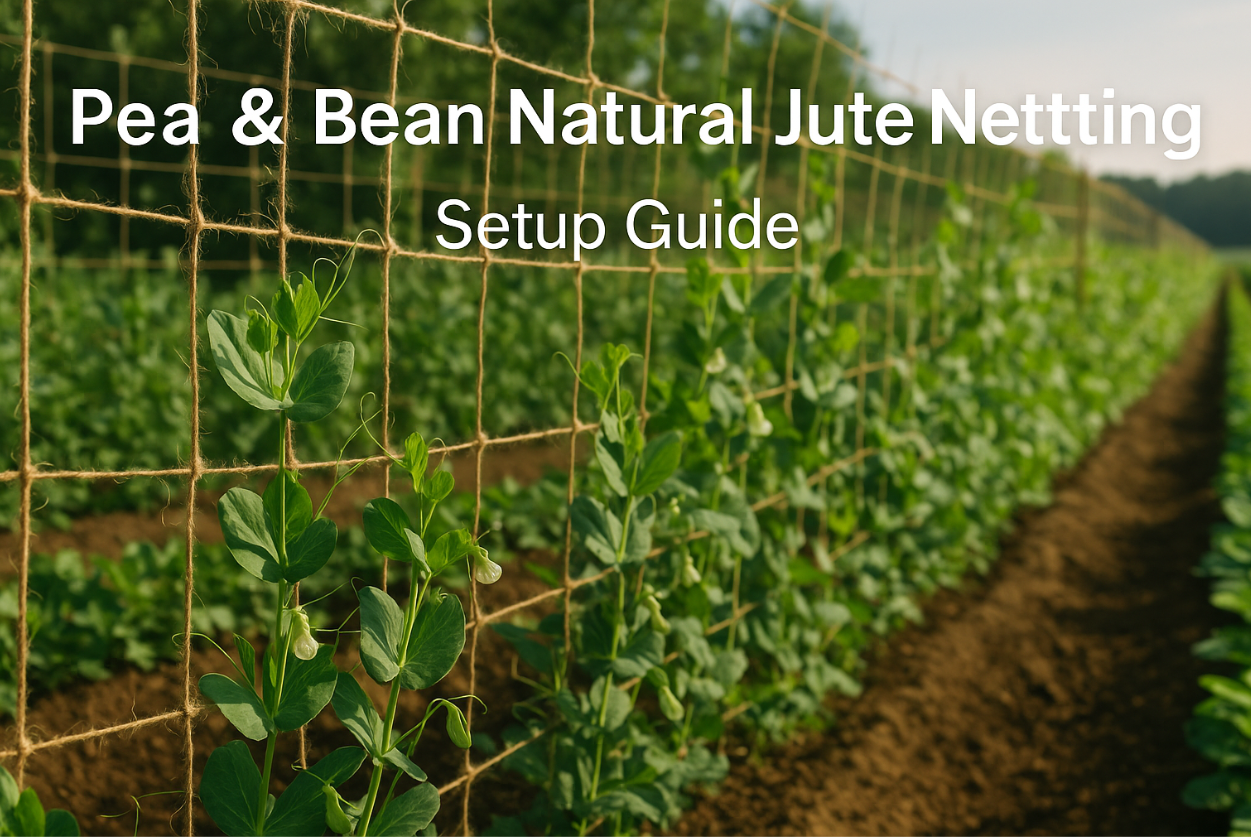

Sustainable vegetable production is no longer a niche concern—buyers and regulators alike now scrutinize everything from inputs to end-of-life disposal. Pea and bean natural jute netting offers growers an easy win: a biodegradable trellis that slashes labor without leaving plastic in the soil or landfill. As a vertically integrated manufacturer and global supplier, Wellco Industries helps contractors, distributors, and OEM partners secure dependable volumes of jute and other erosion-control products while keeping costs predictable and quality consistent.

Understanding Pea and Bean Natural Jute Netting

1.1 What It’s Made Of & Why It Matters

Jute fibers are extracted from Corchorus plants and twisted into two-ply twine before being knotted into netting. Typical tensile strength ranges from 80–120 lbs-force per strand—more than enough for vining peas and pole beans. Independent ASTM-D6400 compostability tests confirm 90 % mass loss within 12 months in active compost, so there’s no microplastic legacy.

1.2 Environmental & Regulatory Benefits

Switching just one acre of plastic trellis to jute keeps roughly 150 lb of polypropylene out of the waste stream each season (USDA Conservation Innovation Grant, 2023). The material meets NOP organic guidelines, and many state cost-share programs reward biodegradable netting. “Healthy soil biology thrives when synthetic residues are removed from the rotation,” notes Dr. Ana Lopez, agronomist at the Mid-Atlantic Sustainable Ag Center.

Planning Your Installation

2.1 Assessing Site & Crop Requirements

Start by mapping row length, prevailing wind direction, and any low-lying areas that trap moisture. Beans can climb 6-8 ft; peas prefer 4-6 ft. Align rows north-south where possible to balance sun exposure.

2.2 Selecting Mesh Size, Length, and Support Hardware

Mesh openings of 4 in suit snap peas; 6 in allows hand harvest of Romano beans. Roll lengths from 500 ft to 3,000 ft minimize joins. Wellco Industries offers private-label cartons and bundles paired with 1/2-in fiberglass stakes, simplifying one-pallet purchasing.

2.3 Crew Safety & Ergonomic Prep

Provide cut-resistant gloves, safety glasses, and knee pads per ANSI/ISEA standards. Pre-stretch netting on sawhorses to reduce back strain in the field.

Step-by-Step Setup Guide (The “How”)

3.1 Tools & Materials Checklist

-

Fiberglass or steel ground stakes (8 ft)

-

Top wire (12-gauge)

-

Zip ties or biodegradable jute lashings

-

Measuring tape & post driver

3.2 Installing Ground Stakes & Overhead Wires

Drive stakes every 10 ft, leaving 18 in above soil. String the top wire taut and level; this carries 70 % of vine load.

3.3 Securing and Tensioning the Jute Netting

Unroll the netting along the row, clipping the top selvage to wire first, then anchoring the bottom to ground pins. Maintain 15–20 lb of tension to prevent mid-season sag.

3.4 Avoiding Common Mistakes

-

Sagging: add mid-span stakes on runs over 100 ft.

-

Knot failure: knot tails ≥ 2 in to resist UV degradation.

-

Choking stems: keep the bottom edge 4 in above soil so new growth can find the mesh.

Maximizing Crop Performance Post-Installation

4.1 Training Vines for Optimal Airflow & Light Penetration

Guide the first runners manually every other stake; studies at Cornell showed 18 % lower mildew incidence when early training improved airflow.

4.2 Irrigation, Fertility, and Integrated Pest Management Tips

Use drip lines at 0.4 gph emitters; overhead irrigation can weigh down jute. Foliar feed with 1 % fish hydrolysate weekly until bloom. Deploy yellow sticky traps at canopy height to monitor aphids.

4.3 Weekly Maintenance & End-of-Season Composting

Trim broken strands, tighten zip ties, and clear leaf debris. After harvest, cut netting at ground level and compost on-farm; the carbon-rich jute boosts C:N balance.

Real-World Results & Cost Analysis (The “Why”)

5.1 Case Study: 30 % Labor Savings on a 10-Acre Midwest Veg Farm*

A diversified grower replaced plastic trellis with jute across 10 acres. Setup hours fell from 210 to 148 and teardown shrank from 55 to 6 hours—total labor savings: $3,240 at $20/hr. Yield per linear foot rose 6 % thanks to better vine spacing.

5.2 ROI vs. Synthetic Trellis Netting

| Cost Item (per acre) | Plastic Netting | Jute Netting | Year-2 Netting & Disposal |

|---|---|---|---|

| Material | $280 | $350 | $0 (compost on-farm) |

| Labor Setup | $420 | $300 | $0 |

| Disposal/Removal | $150 | $0 | $0 |

| 2-Year Total | $850 | $650 | — |

Break-even occurs in the first season when factoring disposal and reduced labor.

Conclusion

Pea and bean natural jute netting delivers tangible gains—lighter environmental footprint, faster installation, and measurable cost savings. Ready to spec sustainable trellising on your next job? Contact Wellco Industries for a tailored quote or private-label program that fits your acreage and supply-chain needs.

Frequently Asked Questions

Q1. How long does jute netting last in the field?

Expect a full-season lifespan of 4–6 months; UV-stabilized twine options can stretch to 9 months in high-sun regions.

Q2. Can I custom-order different mesh sizes or roll lengths?

Yes. Wellco Industries offers OEM runs with mesh from 3 in to 8 in and rolls up to 5,000 ft, boxed or palletized to your spec.

Q3. Will the netting compost in cooler climates?

Decomposition slows below 55 °F. Shred the used netting and mix with high-nitrogen material like manure to accelerate breakdown.

Q4. Does jute affect soil pH or nutrient balance?

Jute is nearly neutral (pH ≈ 6.8) and contributes about 0.7 % nitrogen by weight as it degrades—negligible but beneficial organic input.

Q5. What is the lead time for bulk orders?

Typical lead time is 2–4 weeks; rush production slots are available during peak planting windows.