- June 4, 2025

- Posted by: wellcoindustries

- Category: Rebar

Introduction

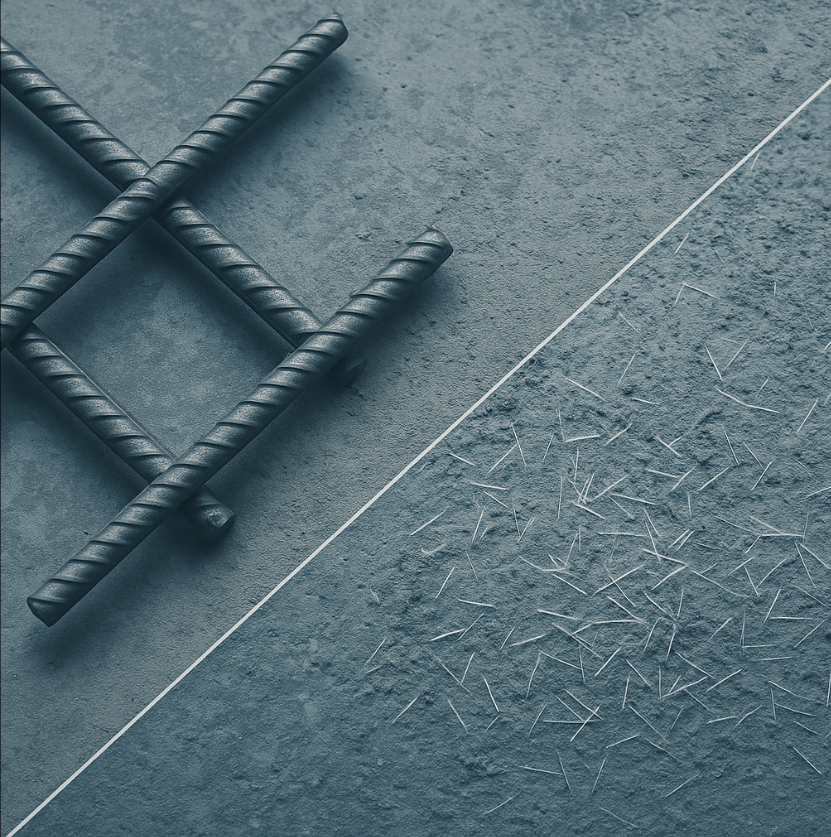

Concrete may be “rock‑solid,” yet every contractor has watched a freshly placed slab spider‑crack before the finishers even leave the job site. Choosing the right reinforcement is the most direct way to stop that from happening—and that’s why the fiber vs rebar debate is so fierce. This article breaks down where each option excels so purchasing managers, specifiers, and field crews can make confidence‑backed decisions. As a vertically integrated supplier of FRP, erosion‑control, and construction inputs, Wellco Industries has supported projects in 40 + countries, giving us a data‑rich view of how reinforcement choices play out on real jobsites.

Understanding Reinforcement Options: Fiber vs Rebar

Composition & Manufacturing Processes

“Reinforcement isn’t one-size-fits-all; it’s engineered metallurgy or chemistry welded to real‑world logistics.” — Carlos Vega, P.E., Structural Materials Consultant

Standard carbon‑steel rebar (ASTM A615) is hot‑rolled, ribbed for bond, and cut or bent to match slab geometry. Structural fibers are manufactured in millimeter‑scale lengths—macro‑synthetic polypropylene, alkali‑resistant glass, micro‑steel, or basalt—then dosed into the ready‑mix truck by weight (typically 1.5–7.5 lb/yd³). The result is a three‑dimensional network dispersed through every cubic inch of concrete.

Typical Applications in Agriculture & Construction

Slabs‑on‑grade, precast panels, manure containment ponds, erosion‑control mats, and greenhouse floors all rely on crack control. In 2023 a 4,500 m² dairy barn floor in the U.S. Midwest replaced #4 rebar mats with 4 lb/yd³ macro‑synthetic fiber, eliminating 380 labor hours of bar tying while meeting the same service‑load crack‑width limits.

Performance Comparison in Key Criteria

Tensile & Flexural Strength Data

ASTM C1609 beam tests show that 5 lb/yd³ macro‑synthetic fiber lifts residual flexural strength to 650 psi at L/600 deflection—about 38 % higher than plain concrete—while #4 rebar at 12 in. o.c. offers 0.6 in‑lb/in² toughness after cracking. A 2024 ACI database review notes, “Fiber reinforcement provides post‑first‑crack ductility that rivals light rebar grids for many slab‑on‑grade loads.”

Crack Control & Shrinkage Reduction

Because fibers form a microscopic web, they arrest plastic shrinkage cracks within the first six hours—an area rebar cannot touch. A University of Kansas field study logged a 58 % reduction in average crack width (0.28 mm vs 0.67 mm) on fiber‑only test panels poured side‑by‑side with rebar mesh.

Durability in Aggressive Environments

Steel rebar loses up to 40 % cross‑section after 20 freeze‑thaw cycles in chloride‑rich splash zones, but polypropylene or glass fibers are immune to rust. Epoxy‑coated rebar improves longevity, yet adds roughly $0.27 /lb and still requires careful handling to prevent coating damage.

Cost & Installation Considerations

Material & Labor Cost Breakdown

| Reinforcement | Material Cost (US $ / yd³) | Labor (hrs / 100 ft²) |

|---|---|---|

| #4 Rebar @12 in. o.c. | 16.40 | 2.8 |

| Macro PP Fiber 4 lb/yd³ | 11.80 | 0.9 |

RSMeans Q4 2024 National Average

Job‑Site Efficiency & Safety Impacts

Wellco field technicians logged a tilt‑up warehouse pour that finished 20 % faster when the crew switched from welded‑wire mesh to a 5 lb/yd³ macro‑fiber dosage—no cutting, no chairs, zero back injuries from tying wire. That hours‑saved number frequently decides the fiber vs rebar contest on tight schedules.

Sustainability & Lifecycle Analysis

Embodied Carbon & End‑of‑Life Scenarios

A 2023 University of Ottawa LCA showed that replacing mesh with macro‑synthetic fiber in a 30 MPa slab trimmed embodied CO₂ by 12 kg/m³ (≈ 7 %) thanks to lower steel use and fewer truckloads. End‑of‑life steel recycling is an advantage for rebar, but polypropylene fiber can be incinerated for energy recovery under ISO 21930 waste‑to‑energy credits.

Specifying Greener Projects

When a Pacific NW municipality sought LEED v4 MR credits on a bike‑path overlay, designers opted for alkali‑resistant glass fibers at 3 lb/yd³. The path met strength specs while earning one additional point for recycled‑content substitution versus epoxy‑coated steel.

Choosing the Right Reinforcement: Decision Framework

Project Assessment Checklist

-

Load Type – wheel loads, point loads, dynamic impact?

-

Exposure Class – chlorides, sulphates, animal waste?

-

Joint Spacing & Thickness – larger panels favor fibers for micro‑crack control.

-

Placement Constraints – congested rebar may hinder vibrator access.

-

Specification Language – does the engineer permit alternative reinforcement?

When Hybrid Approaches Make Sense

Many high‑demand floors marry 3 lb/yd³ macro‑synthetic fiber for shrinkage control with minimal #5 rebar under column lines to handle punching shear. Hybrid designs keep total steel tonnage down while preserving structural margin—one reason Wellco’s mix‑design team often proposes “fiber plus rebar” instead of a binary choice.

Conclusion

Concrete reinforcement is a balancing act among strength, constructability, and long‑term durability. Steel bar still rules where primary tensile capacity or design heritage demands it, yet fibers shine for crack control, speed, and corrosion immunity. By weighing objective data and job‑site realities, you can select the mix—or hybrid—that delivers a slab worthy of your reputation. Contact Wellco Industries for mix‑design assistance or a no‑pressure quote on the full range of FRP and reinforcement solutions.

Frequently Asked Questions

Q1. Will fiber change the look or finish of my slab?

Properly dosed macro‑synthetic or glass fibers stay below the surface; experienced finishers report no fuzz after power troweling and curing.

Q2. Can fibers completely replace rebar in structural walls?

For walls resisting sizable bending moments, engineers usually specify at least minimal rebar cages; fibers alone are more common in slabs‑on‑grade and overlays.

Q3. Does fiber‑reinforced concrete need different joint spacing?

Joint layout often remains the same, but many contractors safely extend spacing 10–15 % because fibers reduce shrinkage stress. Confirm with your engineer.

Q4. How is fiber added at the batch plant?

Bags are slit or dosed via automated hopper into the drum, then mixed for 60–90 seconds to ensure uniform dispersion before water adjustment.

Q5. What’s the delivery lead time for large fiber orders?

Wellco stocks common dosages regionally; most U.S. orders ship within 48 hours, while international containers dispatch in one to two weeks.