- June 13, 2025

- Posted by: wellcoindustries

- Category: Fiberglass fire blanket

Introduction

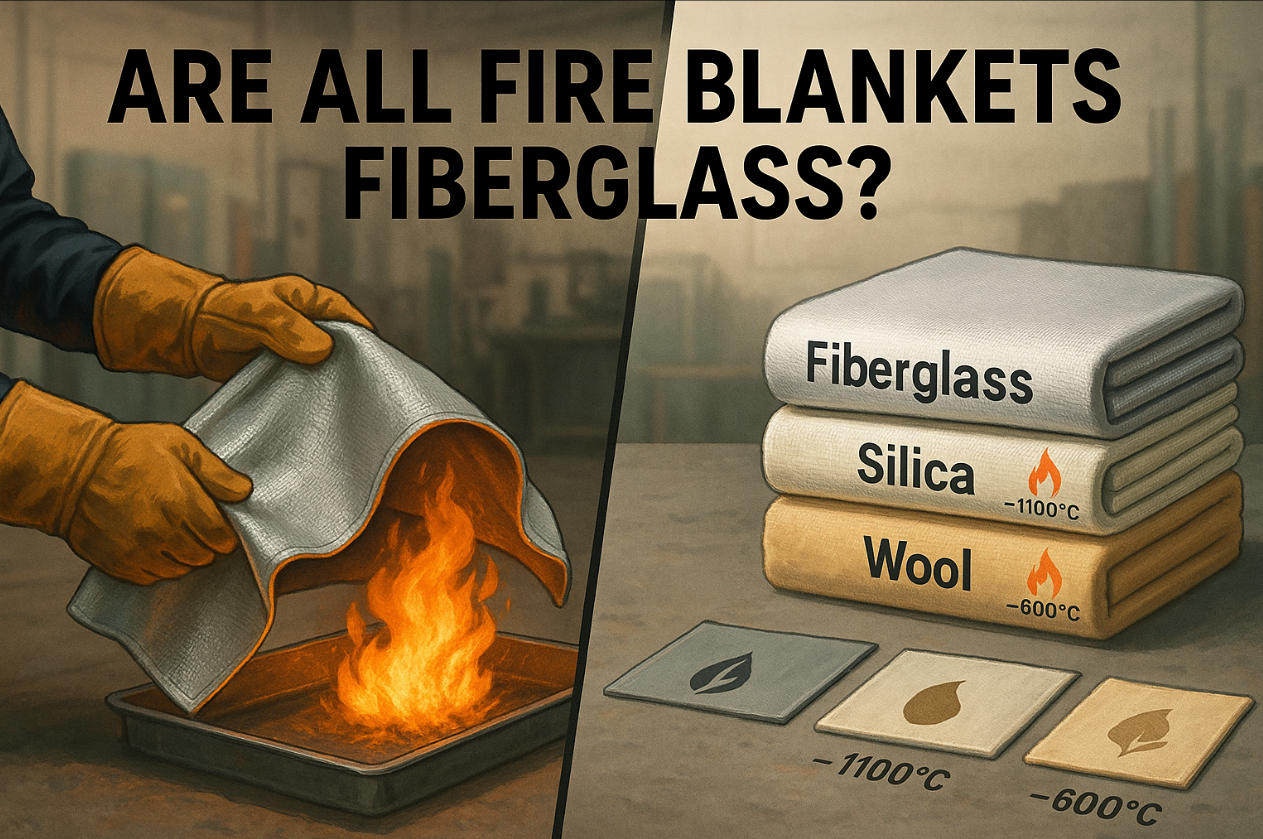

Imagine grabbing the nearest cloth to smother a small flame, only to see it ignite instead. Material matters when seconds count. The debate “are all fire blankets fiberglass” surfaces on every safety-equipment forum because the answer affects compliance, insurance, and—most importantly—lives. Fiberglass dominates for good reasons, but alternatives have their place.

As a vertically integrated manufacturer, Wellco Industries supplies both standard fiberglass blankets and specialty high-temperature fabrics to contractors, farms, and OEM buyers worldwide. Decades of composite experience inform the practical guidance below, helping you choose the right blanket the first time.

Understanding Fire Blankets and Their Materials

What Exactly Is a Fire Blanket?

A fire blanket is a flexible sheet engineered to starve small fires of oxygen. Most consumer and light-industrial models carry EN 1869 or ASTM F1989 labels and are designed for one-time use on incipient Class A and hot-grease fires. Think of them as the first rung on the fire-safety ladder—quicker than a fire extinguisher and safer in cramped spaces.

Stat: In a 2024 UL field study, 73 % of kitchen flare-ups were fully suppressed by a correctly deployed blanket within 15 seconds.

How Fiberglass Fire Blankets Work

Fiberglass consists of continuous glass strands woven into a satin or twill fabric that will not burn and only softens above 1,200 °C (2,192 °F). A thin silicone or acrylic coating makes the cloth pliable and keeps fibers from fraying. When draped over flames, the blanket seals the fire from oxygen while reflecting radiant heat away from the user’s hands.

Are All Fire Blankets Fiberglass? Separating Fact from Fiction

Why Fiberglass Became the Industry Standard

According to a 2023 CEN market brief, fiberglass accounts for roughly 85 % of fire-blanket sales across the EU and North America. It wins on:

-

Cost-effectiveness – glass yarn is abundant and easily woven.

-

Low weight – 0.4–0.9 kg for a 1 × 1 m home unit.

-

Size range – from pot-lid squares to 2 × 3 m welding drapes.

Alternatives: Wool, Kevlar®, Silica & Aluminized Fabrics

Not every scenario suits fiberglass.

-

Wool: treated with flame retardants; tolerates ≈ 570 °C. Works for dorm kitchens.

-

Aramid (Kevlar®): handles sparks and sharp edges but costs 4–5 × more.

-

Silica (96 % SiO₂): continuous service to 1,000 °C; perfect for lithium-battery labs.

-

Aluminized fiberglass or silica: outer foil layer reflects 95 % radiant heat; common on refinery hot-work pads.

When prospects ask “are all fire blankets fiberglass,” the real takeaway is that the right blanket depends on the heat source, budget, and regulatory code.

Selecting the Right Blanket for Agriculture, Construction & OEM Needs

Performance Specs Purchasing Managers Should Check

Before issuing a purchase order, verify:

-

Fabric weight & weave density (e.g., 430 g/m² plain weave vs. 600 g/m² satin).

-

Temperature rating and any coating (silicone, PTFE).

-

Edge reinforcement—lock-stitch or bias binding prevents unraveling in the field.

-

Private-label options for OEM or distributor branding.

A Wellco product engineer can translate these specs into part numbers, saving back-and-forth emails.

Application-Based Recommendations

| Scenario | Recommended Material | Why |

|---|---|---|

| Hot-work curtains on construction site | 0.8 mm silicone-coated fiberglass | Flexible, rugged, economical |

| Kitchen or food-truck grease fire | 0.43 mm plain fiberglass | Quick fold, easy wall mount |

| Greenhouse heater proximity shield | 1.2 mm vermiculite-coated fiberglass | Humidity resistance |

| Lithium battery test chamber | 0.7 mm silica cloth | Survives thermal runaway |

Wellco’s one-stop supply model means mixed-material orders ship together, simplifying logistics for multi-site contractors.

Experience in the Field: Case Study & Expert Insights

Case Study – Contractor Avoids Downtime with High-Temp Silica Blanket

A Midwestern highway contractor scheduled nightly bridge-deck welding. Fiberglass blankets began glazing after repeated 1,000 °C torch flashes, risking drip-through. Switching to Wellco’s 0.9 mm silica cloth avoided a projected 48-hour shutdown, saving an estimated US $27,000 in rental and labor overruns.

Expert Quote on Certification Gaps

“A blanket is only fit for duty if the label is legible and the crew knows what it means,” says Maria L., CFPS, who audits industrial safety programs. Her 2023 survey found 1 in 6 field blankets missing required EN 1869 markings, exposing companies to citation and liability.

Maintenance & Compliance Best Practices

Storage, Inspection, and Replacement Intervals

-

Mount cabinets no higher than shoulder level and within 10 m of risk points.

-

Conduct a 12-month visual and tactile check: stiffness, discoloration, loose hems.

-

If fibers crumble under a light rub or the blanket smells acrid, retire it.

-

Use the NFPA 705 field flame test for quick field validation.

Training Staff for Rapid Deployment

Drills boost recall under stress. A proven three-step script:

-

Pull the tabs to release.

-

Wrap hands inside top edge for burn protection.

-

Cover & hold until flames are out, then leave blanket in place until cool.

Wellco QR-code hang-tags link directly to a 45-second video, making refresher training almost effortless.

Conclusion

Material choice dictates whether a blanket quenches a flame or feeds it. Fiberglass covers most everyday risks thanks to high melt points and affordable pricing, yet wool, aramid, or silica fabrics outshine it in niche, high-temperature jobs. Assess your hazards, confirm temperature ratings, and build a maintenance plan. For spec sheets, bulk quotes, or custom composite solutions, reach out to Wellco Industries—your partner in keeping people, projects, and property safe.

Frequently Asked Questions

Q1. Can I fold a fiberglass blanket after use and keep it for emergencies?

Yes, as long as fibers show no glazing or breakage and certification labels remain legible; otherwise replace immediately.

Q2. Do silica or aramid blankets require special storage?

Store them in a dry, UV-shielded cabinet just like fiberglass, but avoid sharp folds that can weaken silica yarns over time.

Q3. How often should a commercial kitchen replace its blankets?

Perform annual inspections; most operators budget replacement every 3–5 years depending on wear and local health-department rules.

Q4. Can Wellco customize blanket sizes for OEM kits?

Absolutely—cut panels, stitched grommets, and private-label packaging are available with standard lead times.