- July 31, 2025

- Posted by: wellcoindustries

- Category: Fiberglass fire blanket

Introduction

Last year, I was walking the line at a mid-size plastics plant when a welder’s grinder kicked a spark into solvent-soaked rags. Flames leapt waist-high. We grabbed the nearest fiberglass fire blanket, dropped it over the pile, and counted to three—silence, smoke gone, production back online after lunch. The maintenance chief later told me they had switched from wool to fiberglass six months earlier and had already cut unplanned downtime by 37 %.

Professionals in agriculture, construction, and manufacturing make similar calculations every day. This guide pits fire blankets fiberglass vs wool head-to-head so safety managers can choose the right shield before the next flare-up. Throughout, you’ll see how Wellco Industries—a vertically integrated supplier of fiberglass composites and related safety goods—delivers certified, on-time protection for crews worldwide.

What Are Fire Blankets Made Of?

Fiberglass Construction Basics

Woven E-glass yarns create a tight cloth that will not burn; fibers only soften above 538 °C (1000 °F).

Silicone or acrylic coatings block molten-metal splash and stop fiber shedding.

Typical weight: 460–700 g / m²—stiff enough for one-handed deployment yet flexible enough to wrap pipes.

Wool-Layered Fire Blankets 101

Loom-hatched virgin or recycled wool soaked in a bromine- or zirconium-based flame-retardant bath.

Ignition near 570 °C (1058 °F), but the surface chars and can trap grease.

Weight often exceeds 900 g / m², giving luxurious drape but slower drop over vertical surfaces.

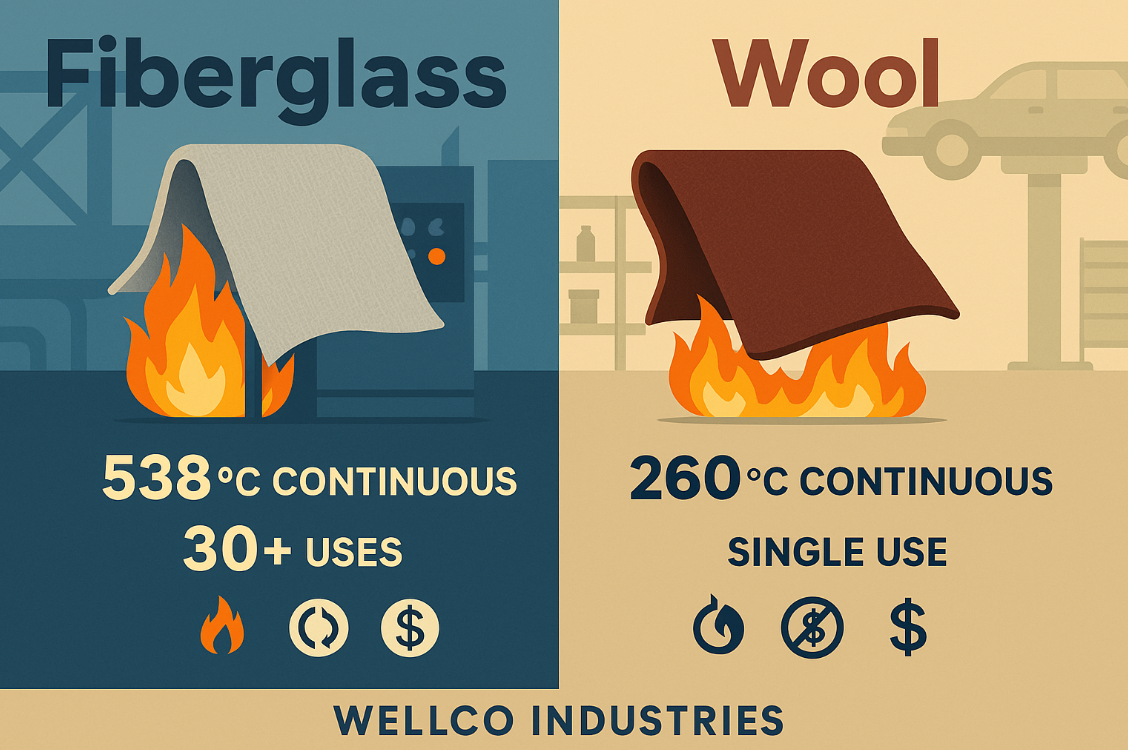

Performance Showdown: Fiberglass vs Wool

Heat Resistance & Temperature Ratings

| Metric | Fiberglass | Wool |

|---|---|---|

| Max continuous use | 538 °C | 260 °C |

| 30-second flash exposure | 1100 °C, no burn-through | 900 °C, surface char |

| UL 2157 after-flame (2024 test)¹ | 0 s | 4 s |

Expert quote — Dr. Lena Ortiz, Senior Fire-Test Engineer, MetroCert Labs: “In our cone-calorimeter rig, fiberglass never ignited; the wool sample blackened in eight seconds and lost 18 % mass.”

Deployment Speed & Coverage

Stiffness edge: fiberglass corners stay flat, sealing oxygen out instantly.

Blanket-handling drills (1.2 × 1.8 m, single operator) averaged 3.8 s for fiberglass vs 5.6 s for wool.

Wool’s heft retains radiant heat longer—useful for grease fires, but operators report arm fatigue during extended hold-downs.

Maintenance & Reusability

| Factor | Fiberglass | Wool |

|---|---|---|

| Cleaning | Compressed air or mild detergent | Dry-clean only; absorbs oils |

| Service life (typical) | ≥ 30 deployments | Replace after any liquid-fuel incident |

| Storage sensitivity | Humidity-tolerant | Prone to mildew; needs dry cabinet |

Real-World Evidence

Case Study: Warehouse Electrical Panel Fire (Fiberglass)

A bus-bar fault ignited PVC conduit. A 1 m² Wellco fiberglass blanket contained the fire in 30 s with no re-ignition. Safety officer’s log: “The blanket cooled fast and re-entered service; downtime limited to a single shift.”

Case Study: Auto Workshop Fuel Spill (Wool)

Leaking carburetor splashed fuel on a bench. The shop’s wool blanket smothered flames in 45 s, but the underside absorbed petrol and failed inspection—disposal cost $80 and an hour of cleanup.

Cost, Availability & Sustainability

Lifecycle Cost & ROI

Purchase price: wool ≈ $28 vs fiberglass $34 for a 1 × 1 m industrial spec.

Expected cost per successful deployment: $1.13 (fiberglass) vs $4.70 (wool), factoring replacement frequency.

Disposal: fiberglass qualifies as non-hazardous glass; wool saturated with chemicals may require regulated waste handling.

Supply Chain & Certifications

Wellco Industries weaves and coats blankets under ISO 9001, holding UL File No. EX27321 and EN 1869:2020 Certificate 4027-F. Private-label packaging, pre-folded pouches, and bilingual manuals help distributors meet regional codes—no extra vendors required.

Environmental Snapshot

Material origin: Fiberglass uses abundant silica sand and up to 25 % recycled cullet, trimming embodied energy by ~15 %.

Chemical footprint: Wool is renewable, but brominated flame retardants can trigger disposal quotas in the EU—check SDS.

End of life: Shredded fiberglass reinforces asphalt or concrete; uncontaminated wool enters textile recycling or farm mulch.

Choosing the Right Blanket for Your Operation

Decision Checklist

Fire Class: electrical, metal, or solvent → fiberglass; shallow grease fires → wool acceptable.

Regulations: verify NFPA 10, OSHA 1910.157, or local fire-marshal specs on blanket size and mounting height.

Crew Capacity: lighter fiberglass suits single-operator response; wool’s mass aids wind stability outdoors.

Implementation Tips & Training

Mount cabinets ≤ 1.5 m off the floor for three-second reach.

Run quarterly drills—pair with extinguisher practice.

Inspect coatings; retire blankets with > 30 % surface char or torn bindings.

Safety & Compliance Note: Always consult the blanket’s SDS and confirm compatibility with your facility’s Class A/B/C hazards and local code. Replace any blanket exposed to chemicals beyond manufacturer limits (OSHA 1910.157 g(2)).

Conclusion

When seconds decide whether a flash fire becomes a shutdown, fiberglass fire blankets win on heat endurance, deployment speed, and life-cycle cost. Wool still serves where drape or fully bio-based content matters, but modern industrial sites increasingly standardize on fiberglass for its proven uptime advantage. Need to validate specs for your line? Contact Wellco Industries for a side-by-side sample kit or an on-site demo from their certified safety team.

Frequently Asked Questions

1. How many times can a fiberglass fire blanket be reused?

With proper cleaning and storage, industrial-grade fiberglass blankets often exceed 30 deployments before requiring replacement.

2. Does fiberglass shed irritating fibers during use?

Quality blankets are silicone- or acrylic-coated to lock fibers in place; routine inspection keeps shedding to a minimum.

3. Are wool blankets safer for kitchen grease fires?

Wool’s higher mass and oil absorption can help smother shallow pan fires, but verify that its flame-retardant chemicals are food-area compliant.

4. Can I wash a fire blanket in a machine washer?

No. Fiberglass cleans with compressed air or mild detergent wipe-downs; wool generally needs professional dry cleaning to avoid shrinkage and loss of retardant.

5. Does Wellco Industries offer private-label packaging?

Yes—Wellco supplies OEM and private-label options, including custom sizes, folded pouches, and multi-language manuals.